Spheroidal graphite cast iron or ductile cast iron or nodular cast iron

| EN-GJS-XXX-YY |

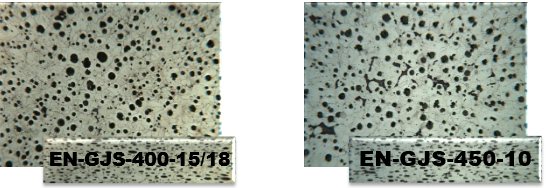

Ferritic Spheroidal cast irons

| # | Material designation Symbol | Material designation Number | 0,2 % Proof strenght (Rp0,2/MPa/min) | Tensile strenght (Rm/MPa/min) | Elongation (a % min) | Brinell hardness (min-max) |

|---|---|---|---|---|---|---|

| 1 | EN-GJS-400-18 | 5.3105 | 250 | 400 | 18 | 160-180 |

| 2 | EN-GJS-400-15 | 5.3106 | 250 | 400 | 15 | 160-180 |

| 3 | EN-GJS-450-10 | 5.3107 | 310 | 450 | 10 | 160-180 |

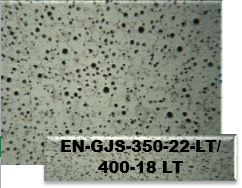

High-impact strength Ferritic Spheroidal cast irons

| # | Material designation Symbol | Material designation Number | 0,2 % Proof strenght (Rp0,2/MPa/min) | Tensile strenght (Rm/MPa/min) | Elongation (a % min) | Brinell hardness (min-max) |

|---|---|---|---|---|---|---|

| 1 | EN-GJS-350-22-LT | 5.3100 | 220 | 350 | 22 | 140-170 |

| 2 | EN-GJS-400-18-LT | 5.3103 | 240 | 400 | 18 | 160-180 |

Micrographies of the castings we produce.

Ferritic-Pearlitic Spheroidal cast irons

The ferritic-pearlitic spheroidal cast irons have a mixed matrix composed from ferrite and pearlite.

They are obtained by adding pearlite formers such as Copper (Cu), Chromium (Cr) and Tin (Sn).

They have intermediate properties between the ferritic cast iron and the pearlitic one and have a good workability.

| # | Material designation Symbol | Material designation Number | 0,2 % Proof strenght (Rp0,2/MPa/min) | Tensile strenght (Rm/MPa/min) | Elongation (a % min) | Brinell hardness (min-max) |

|---|---|---|---|---|---|---|

| 1 | EN-GJS-500-7 | 5.3200 | 320 | 500 | 7 | 170-190 |

| 2 | EN-GJS-600-3 | 5.3201 | 370 | 600 | 3 | 190-230 |

Micrographies of the castings we produce.

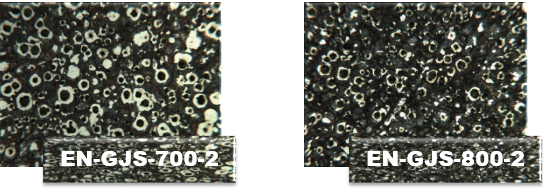

Pearlitic Spheroidal cast irons

The pearlitic spheroidal cast irons have a matrix almost completely pearlitic, with small amounts of ferrite around the graphite nodules.

They posses a high tensile strength, good wear resistance and a moderate machinability.

| # | Material designation Symbol | Material designation Number | 0,2 % Proof strenght (Rp0,2/MPa/min) | Tensile strenght (Rm/MPa/min) | Elongation (a % min) | Brinell hardness (min-max) |

|---|---|---|---|---|---|---|

| 1 | EN-GJS-700-2 | 5.3300 | 420 | 700 | 7 | 170-190 |

| 2 | EN-GJS-800-2 | 5.3301 | 480 | 800 | 3 | 212-280 |

Micrographies of the castings we produce.