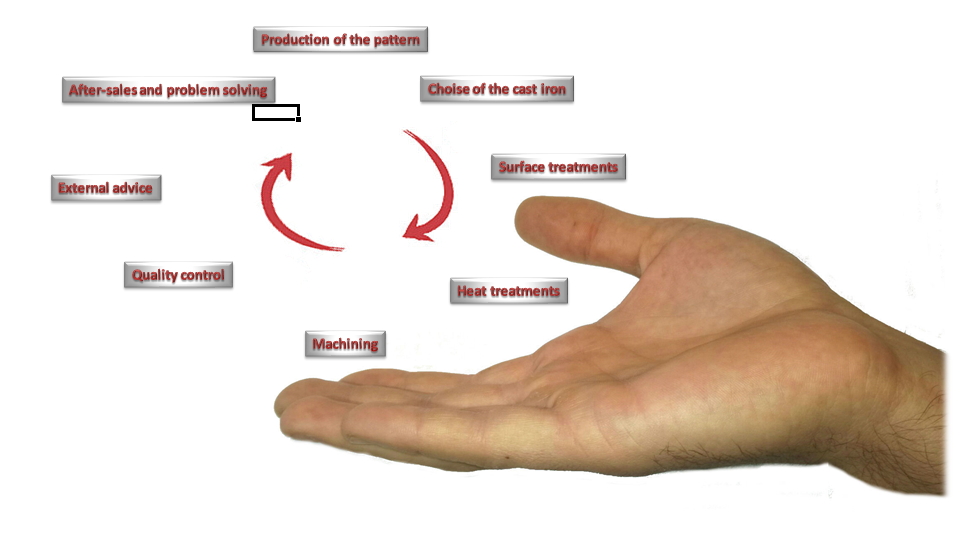

Our technicians, with decades of experience in foundry field, will guide the customer from the realisation of the pattern, to the cast iron type most suitable choice and possible subsequent processing.

Our castings are subject to specific controls to guarantee the high quality of the product.

- wood

- resin

- polystyrene

- metal

We employ expert external mechanical pattern-making unit equipped for the construction of patterns in different materials.

The realisation of the pattern, according to customer requirements and the technical requirements of the foundry, will be made by considering the ratio quantity / price of the equipment.

The patterns , whose ownership will be the customer, are stored in special warehouses covered and labeled with "Customer Name" and "Id Number" for instant traceability.

The loading and unloading are managed by a specific management software.

- Deflashing

- Shot blasting

- Painting

- Internal ducts cleaning tested with endoscope

Some operations can be performed within our structure, otherwise we employ expert and specialized companies.

They can be performed single components or epoxy painting, spraying or dipping.

- Ferritization

- Normalization

- Stabilization

- VT - Visual Testing, visual control system.

- Chemical analysis

- HB - Brinell Hardness

- Micrography

- Sectioning of the casting (sample)

Fonderia Carroccio has a fully equipped laboratory for the control of : chemical analysis, metallographic structure of the cast iron, hardness.

- PT - Penetrant testing

- RT - Radiography testing - X-ray systems

- UT - Ultrasonic testing

- MT - Magnetic Particle Testing

- Dimensional inspection

- Mechanical testing (Yield stress - Tensile strength - Elongation - Impact test - Brinell Hardness)

In order to ensure a further casting quality are carried out, on customer's request, several non-destructive testings (NDT) using trusted external highly qualified and certified companies.

An established quality policy has allowed us, over the years, to handle any type of problem arising in the post sale.

Any non-compliance will be immediately taken over by staff who will immediately research, troubleshooting and monitoring the same over time. Our supplies are always performed according to the:

General Condition of Contracting for European Foudries